For the last year or so, since I have been pushing the power limits of the Q-Tronic Gearbox, I have had an issue that has been getting progressively worse, as the power increased.

For those that don’t know, the Q-Tronic gearbox in the Alfa 159 is actually a Aisin Warner TF80-SC, also known as the AF40-6. This is a complex automatic 6 speed gearbox that has the combined use of a conventional 5-pinion planetary gear-set and a compound Ravigneaux gearset which makes it incredibly light and compact. This combination is known as a Lepelletier arrangement. The shifting of gears is managed by a computer programme which oversees a clutch-to-clutch actuation. Gear changes are accomplished by one clutch engaging the instant the clutch from the previous gear disengages. (Source https://en.wikipedia.org/wiki/AWTF-80_SC). This gearbox is used in an extensive list of modern vehicles and is a very strong and versatile unit.

While the power being fed into the gearbox was within manufacturer tolerance, i.e upto 450-500nm everything was just fine and every gear-change was silky smooth, however, as soon as pushed the power north of 500nm I started to have issues.

Essentially, the problem manifest as one of two common issues often associated with a worn or damaged valve body. These were:

- Shift Flairs – The gearbox engages the first clutch to allow for the second gear to be engaged and takes a few milliseconds longer than it should to disengage the first clutch and engage the second resulting in the RPM’s have a 500rpm flair on the gear change.

- Missed Shifts – The gearbox engages the first clutch to allow for the second gear to be engaged and takes a few seconds longer than it should to disengage the first clutch and engage the second resulting in the RPM’s hitting the red line and staying their until the clutches caught up with each other resulting in the next gear being SLAMMED in from 5K RPM to 3KRPM.

Neither of the above problems are particularly nice to experience and needed resolving.

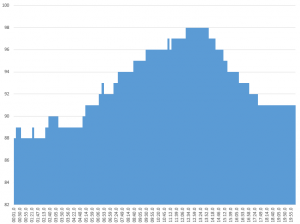

In about May 2015, I noticed that the issues were related to me “driving in a spirited manner” and as such I decided to monitor the gearbox temperatures to see if that was part of the issue. This quickly showed that the issues only manifested once the gearbox oil exceeded 90 degrees C. The following data log graph shows the temps hitting 98 degrees C in under 20 minutes of “spirited driving”:

As soon as I pushed the power into the gearbox it became unusable.

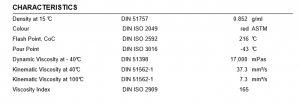

Some research into the oil used in the gearbox showed why heat was the problem. The following extract from the technical specifications of the oil I use in my gearbox (Fuchs Titan ATF 4400), clearly shows that the Kinematic Viscosity of the oil at 40 degrees is 37.3 mm2/s while at 100 degrees it is 7.3 mm2/s. That is a big difference! So, if my oil temp hits 98 degrees the efficiency of the oil to be useful and lubricate is negligible, and in cases where I have seen the temp up to 110 degrees C, I essentially was lubricating the gearbox with water…..

http://www.fuchslubricants.com/titan-atf-4400

This became a real issue in September of 2015 on a trip to the Nurburgring. A combination of an aggressive track and blistering heat meant that the gearbox hit 110 degrees within 1/3 of the track and after only a few corners I was having to limp through gear changes to keep the car moving. Not the most pleasant experience to have on the ring.

From this point onwards I started to research exactly how I could solve the issue.

The gearbox oil cooler is a Laminova type cooler that uses the engines water cooling system to pass water through a block attached to the side of the gearbox that has an oil circuit in it. This allows the water to cool the oil through proximity. all you need to know about oil coolers is here on Mocal’s site: http://www.mocal.co.uk/FAQ.html.

After much thought, the plan was simple. Make the oil cooler a traditional air cooled external unit of larger size so that the harder I pushed, the greater the airflow and the more cooling was available.

To do this, I needed the help of my friendly mechanics, the much trusted and respected Autolusso. Ned and his team have been the ones who do all the work on my car and with the exception of the odd tweak here and there, have been responsible for all of the major modifications made to the vehicle to make it the monster it is today.

I enlisted Ned to help me find and/or design an adapter plate that would allow me to remove the oil cooler that was bolted to the side of the gearbox and replace it with a set of pipes off to a cooler mounted up front. After many conversations with a few different suppliers, we pulled a few different cables, pipes and parts from different makes and manufacturers together and started the research.

We quickly established that there was nothing available or even close to what we needed, so the best shot we could find was a set of oil cooler pipes of a 3 series BMW. These fitted backwards! so at least we had something to play with.

We continued to research and plan over the xmas period until, after a dyno night, I realised my car was about 50 horses down on power from where it should be! This was not amusing, and as such I spent a few weeks looking through my many iterations of the map until I found the one table that I had not carried forward. To cut a long one short, my total injection was being limited to 100mm3 where as it should have been at 130mm3. After a couple of tweaks and a test to 120mm3, the car was flying again, but the gearbox was now very unhappy and it only took a 0-100mph run (not on public roads) to make the gearbox temps over 90 degrees C !!!

So Ned and I decided to bite the bullet and just crack into the mod to see where we ended up.

A suitable cooler was chosen out of a small selection Ned had put out for me:

And we took off the original Laminova cooler to see what the options were. After some initial head scratching we decided what we needed to do was to use the existing cooler as a plate to weld on some BSP fittings, so Ned grabbed the biggest grinder he could find and proceeded to destroy the unit in the name of research!

After a quick session of destruction he disappeared with the remains of the part and resurfaced about 20 minutes later with the finished prototype:

This meant we could bolt the remains of the original cooler back onto the gearbox safe in the knowledge that it would not leak or fall off or otherwise fail!

All that was left was to fit the selected oil cooler in place and run some pipes:

To do this a bracket was manufactured to allow the cooler to live off to the side of the FMIC where it could get a decent airflow (as I had already removed the fog lights and modified my front bumper for greater air flow). We also had to relocate the horns next to the FMIC but this was a straightforward move.

I found the basis of the bracket in one of the many parts bins and assume it was part of a former Alfa that no longer needed it and subsequently donated it to me 🙂

One final mod was to remove the water cooler circuit that went from the EGR to the old cooler and back to the engine. To do this all we had to do was remove the pipes and cut one to make the 4ft of hose now 4 inches!

All that was left was then to put the front bumper back on, top up the fluids, run it round the block and see how it performed!

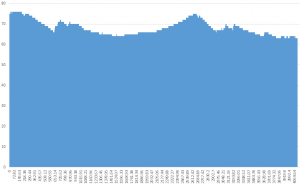

I decided to data log the run home. a Good 90 minutes of M1, A421 & A1 in rush hour traffic, so mixed driving, on and off power and in and out of standing traffic. In order to push the gearbox I deliberately pushed power as much as I could do so safely and often sat in the wrong gear to get things as hot as possible!!

The following graph is of that 90 minutes of mixed driving:

The first thing to point out is that the max temp reached was 76 degrees!!!!!! and the lowest temp, often observed at speed was 63 degrees! This is as perfect an outcome as I could of hoped for as it means the kinematic viscosity of the oil is well within tolerances and effectively lubricating the solenoids so that they can engage and disengage the clutches efficiently!!

The gearbox worked perfectly at all speeds and power levels throughout the entire journey!

Time will of course tell, but early data says this mod is a must have for any owner of an automatic gearbox that wants to unleash the power that their engines are capable of delivering. Trust me when I say, that these gearboxes just lap up the power! (as long as you keep them cool 😉 )

The question is how long it’s going to work properly. The thing is that the gearbox when new can work without fairs up to 127 degrees and heat warning is set at 150. Although it is the best solution/ cheapest solution please report after a year or so if the problem came back.

Had the same issue and usually mechanics want to change the valve body as the pistons when oil is heated cannot sustain the pressure. After removing a piston from the body and sticking one’s finger you can feel how worn the metal is which causes the oil to bypass the piston when viscosity is low.

Vectra with powerful diesels had already mounted separated oil cooler with thermostat.

HI Jabawoki!

Came across this blog on the 159 transmission mod, good work

Just a question on the hacking of the stock heat exchanger unit, do you have any more pictures of the original unit? and the bolt pattern and locations of the in and out points?

I am wondering if it’s the same heat exchanger as Volvo’s (since they both use the same AW-tf80 transmission), and since Volvo’s heat exchange have ports where you can simply run hose to them, if it is swap-able then you save the need for a custom made adaptor plate.

Cheers

Fred

@FredOz I tried to buy a few different sets of adapters from other manufacturers that use this gearbox and the bolt patterns / pipe joins were different which is why in the end, for simplicity I made an adapter out of the existing unit.

I didnt try Volvo because I couldnt find any, but its possible they may fit to save having to make an adapter out of the old cooler.

@Piotr – I will continue to monitor the gearbox and see how the modification holds up over time. What I have done is no different to any other manufacturer though. Many manufacturers offer a “towing pack” option whcih also includes an external cooler for the gearbox. Volvo are an example of this where cars fitted with the standard water/oil unit started to suffer issues when the cars were used in high torque load situations (such as towing). They then created a larger air/oil unit as a replacement to solve the problem.

I am very sure my valve body is quite worn whcih is why the problem occurs at a lower temperature with my car, but the high torque condition from (800nm at the wheels) also contributes to much higher oil temperatures making this modification mandatory for me.

Hi jabbott

Thank you for these useful information . I want to ask you about

the low temp. Because the lack of heating of the engine,how long does the transmission take to reach the operating temp,because is very important.

cheers

fotis

The heating time is not noticeably slower and I have seen no negative effects as a result of the modification.

How did it turn out in the end?

I’m just dong the same mod, so some feed back would be appreciated a lot.

Happy Christmas Richard

It is a must do mod for the QTRONIC.

Alfa should have fitted an external cooler from the factory. The laminova cooler attached to the gearbox is junk IMO. anything more than “driving miss daisy” and it will complain if its over 60K miles and not had an oil change. Top tips for the QTRONINC:

1) Change the oil (1ltr each time) often. its not “oil for life” its just oil, and it gets old. Just drop 1l out the bottom into a jug and put 1l in the top – no hassle.

2) Flush the box every 20k (Google “Gibbons method flush”). Use 20l of oil.

3) If you have anything more than a light remap, put an external oil cooler with a fan and a thermostatic control valve set to 70c on it.

4) If you go for a big power build, limit torque input per gear in the map for 1,2 & 3, eg: (1st <=300nm, 2nd <= 400nm, 3rd <=500nm, 4th <=1000nm, 5th <=1000nm, 6th <=1000nm).

Thats all I can think of. If you treat the box well, and set it up right in the ECU, its a very good box for the big power builds.

Hello,

I’m having the same issue with my 2008 1.9 jtdm ti. Fine when cold but as soon as it heats up start having intermittent flare usually starting 2nd to 3rd then can be in higher gears especially on a long run. Is there a garage that can perform this mod? Or is it a change the valve body time? Any opinions welcomed.

Thanks Stephen

I had the same problem with my Vectra 1.9, but when I installed the external radiator, the transmission came back to life.

Now it works wonders.

I have a 2.4 Q-Tronic also, was thinking of a “small” conversion, aka Q4 and longer gears.

For Q4 there is nothing much to it, getting a Q4 diff from 3.2 Q-Tronic with all the parts needed for rear wheels.

But increasing/longer gears is basically changing output shaft and diff cog to different ratio (which can also be found without a problem) but problem that I have is if gearbox electronic will allow to change final drive ratio, in this I am not sure…

So does any of you know if gearbox electronics looks up at actual car speed, or is it only input and output rpm in the gearbox (with output before output shaft)?

Thanks

Hi JAY,

Did you remap the Aisin TCU as well?

If yes, do you know anyone how can remap the TCU for Alfa 159 3.2 JTS Q4 Tronic to increase gearshift and maybe engine torque?

Thanks

Hi Ivan, Unfortunately, all of the research I did into mapping the TCU yielded zero viable options. I found a reference in the Swedespeed volvo forums to a guy in Europe somewhere that has apparently “done it”, but all other research essentially led to the conclusion that the TCU would need to be removed from the gearbox and manually reverse-engineered on the bench.

There are some values you can control directly from the ECU, such as maximum input torque and torque limiters per gear. These can be adjusted to allow more power than the rated 450NM, but ultimately the gearbox solenoids are not fast enough at clutch changes to handle fast acceleration. As an example, in my Alfa with around 800NM at the wheels, it will “shift flare” between 3rd and 4th if I continue to keep the pedal buried in the carpet as it can rev to 5K faster than the TCU can start the gear change, leaving the RPM’s on the red line while it plays “hunt the gear”. Once the gear is found, it slams all of that “redline” in with zero transition and 100% hurts the gearbox. This is with a brand new torque converter installed on a freshly refurbished gearbox with external cooling and the input torque limited to 400nm in 1st, 2nd and 3rd while 4th, 5th and 6th are all 1000NM limits.

Hey Ranko, So the gearbox is actually monitoring a ton of ECU data and making decisions based on that data. For instance, there is a Yaw sensor in the central tunnel that is used to retard engine power during gearchanges if the Yaw angle is too high, eg. it wont change gear in a hard corner! A lot of these variables can be edited with WinOLS and the relevant Damos files so it is possible to “tune” the gearbox a little, but not much! I do not beleive it looks up the speed, but it relies heavily on the “power calculations” used by the ECU to manage torque creation and delivery, so if you increase the power output of your engine passed a certain point. The gearbox will actually retard the ignition at that point and create a flat line of torque!. I have some fueling logs that show that happening on mine until the relevant variables were changed in the ECU to tell the gearbox that 800NM was only 400NM 🙂

Hi Jay,

Are you saying that it can be possible to achieve more engine torque than 320 nm as declared by Alfa Romeo without remapping the ECU?

Thanks,

Ivan

Hi Jay, to deactivate the yaw sensor, there is a button close to the gear stick… pressing the bottom and hold it down for at least 2 seconds we should deactivate the TCS system and the VDC system. Doing so…. I think the ECU is bypassed and the engine performance should be high, don’t I?🤔

Or maybe the VDC system is always active but with high margine?

Just curious – once you add an auxiliary cooler it looks like the whole transmission fluid capacity rises as there are more pipes to flow through.. Shouldn’t we add more fluid then?

In the meantime I found some external set, I’m wondering if that could do the trick, what do You think:

https://maktrans.net/FK-TF80SCIN

?

thanks!

Yes. You will need to calculate the volume that is held in the new cooler + the pipework and add that to the original volume.

looks reasonable but I have no personal experience of it so it would have to be “try and see”. Dont forget you would need to add the volume for the rad, the pipes and the filter with that kit.

Ivan, I don’t beleive that the yaw sensor is ever deactivated but I may be wrong. pressing the sport/winter button as you describe enables either “sport mode” or “winter mode” Press once for sport, press and hold for winter. in sport mode it holds the gears longer in the rpm range, in winter mode it starts the car in 2nd not 1st and changes gear at lower rpm’s. if you are talking about the VDC off button, another forum user established that the button never actually fully disables the VDC system. There was an additional hardware mod required to disable VDC fully.

Hi Ivan, did you mean the TCU?

You have to modify parameters in the ECU to adjust power output. The gearbox “TCU” has an input limiter that retards injection once it hits the limit as a failsafe. In my 2.4, that limit was 510nm (i think). As you cannot edit parameters in the TCU, you have to change the base variable used for the torque calculation in the ECU. Once you have chosen a suitable variable, this lets the engine “make more power” while the TCU in the gearbox still sees “numbers” within its limits and therefore does not ask the engine to reduce power.

This will 100% damage your gearbox as you are pushing it beyond the safe levels determined by the manufacturer. You do this at your own risk.

Thank You Jay for Your quick response and for describing this whole process. This is the only place I found on the net where someone actually did it.

I’m very surprised there’s so little info on that matter, especially i.e. among Insignia OPC owners who tune their cars high power above 400KM. They might not be aware of what is yet to come…

I heard about such a mod (I believe someone told me, but can’t remember correctly) but when I asked on forums, no one could really tell anything. This mod looks very unpopular while Your temp’s tests and conclusions clearly show how crucial this is for people owning af40.

Do You possibly have some more pictures showing the transmission in a general view so we could see where the pipes should be attached to?

thanks a lot for Your time and for writing this article.

Thanks Charles. There was even less information than this when I started the process so most of this has been learned through trial and error. I am by no means an expert and the information provided is “as is” and devoid of any warranty, implied or assumed 🙂

One thing I will say that is quite important. Dont put a big, slow spooling turbo on like I did. it cant spool fast enough for the gearbox so the car is a bit “laggy” under 2K rpm. its like driving a big lazy cruiser unless you put it in sport mode and force the gearbox to work harder to keep the turbo spooled. Thats the first issue. The second issue is that a big turbo spools the engine faster than the gearbox can actuate a gearchange, and without the ability to adjust the gearchange timimgs in the TCU, the issue is that just results in flares and misses.

My advice, push the borg warner as far as it will go or switch to the Garret from the manual, but don’t significantly increase the wheel sizes within the turbo or you will miss the “sweet spot” balance between teh engine and the box. This 2.4 engine can deliver way more than the AF40 can handle.

All the pictures of the installation are in the gallery at the bottom of this page.

Ok, thanks!

I actually don’t own an Alfa, I own a Saab 9-5 NG 2.8 v6, but the transmission is the same (same engine as Insignia OPC).

Garrett 19T is the one that sits here and my plan is to hit around 400KM, not more, meaning I’d have to make a hybrid 20T only, I presume. In this case, the problem You described shouldn’t be an issue. At least I think so. But thanks for pointing this out.

I tried to find someone who could make any TCU changes and speed it up, but it looks fairly impossible. Even in Europe. The only thing they can do is to take off torque limiters, but that can be set up in the ECU like You described earlier.

They keep on repeating ‘this transmission is shit, slow as hell and there’s nothing You can do about it..’ 🙂

Hi Charles, nice car. I love a Saab and have nearly owned the 2.3T 9-3 a couple of times 🙂 I think your targets are sensible, just watch out for spool times, and you should be fine. Before I started this journey, everyone I spoke to said I was nuts, the gearbox would just disintegrate, and it was a fools errand. Some aspects of those statements are true… but after actually “doing it”, the box isn’t as bad as everyone says. It can handle the power because it has an old-style torque converter, so its better at soaking up the engine power and feeding it into the box. Heat is your enemy and, as I have demonstrated, as long as you can keep the box operating at normal temperatures, you should be just fine. I added a mocal oil thermostat inline to the rad, in the end, to help with heat up times in winter as well as general temperature management. I also added a dedicated oil temp gauge on the dash for the transmision so I could keep an eye on things.

Happy tuning 🙂

yeah, I love NGs, but body parts are very rare and expensive..:)

Thanks anyway, nice to chat! With the knowledge I’ve gained here, my tuning should be easier.

cheers!

Yes, I’m a talking about the VDC off button,… yes, I’ve noticed that the VDC system never actually fully disables itself. Do you know how to install or where to find this additional hardware mod to disable VDC fully. Maybe I have chance to unleash more power from my car.

It seems to be that when I kick the accelerator down with the engine in the max torque range, the engine starts hesitating power for a fraction of second and then power returns again.

And I think this can be the VDC which works in safe mode.

Do you think like that, you too?

Hi Ivan, unfortunately, I am not aware of how to disable VDC, but if you ask in the Performance tuning section of alfaowner.com, people in there have done this and will know how. I am not sure if the issue you describe is the VDC or not.

Hi,

Which oil are you using in your Q-tronic currently?

Millermatic XF Premium MV Extra is what I run. https://www.millersoils-shop.co.uk/xf-premium-atf-mv-extra

hi!

what a perfect article! I have the same problem on my volvo XC70. when describing the faults, mechanics only propose to me to change the gearbox, at least the hydraulic command. so between 2000 and 6500 euros.

Just before reading your article, I bought an OBD reader to connect to my phone and check the oil temperature; to high temperature, up to 105 degrees.

Thanks to your article, I am going to buy and install an additionnal cooler. But, why didnt you install a thermostat?

regards,

hioub

I did eventually add an inline oil thermostat.